PRODUCTIVITY INCREASE AND COST REDUCTION

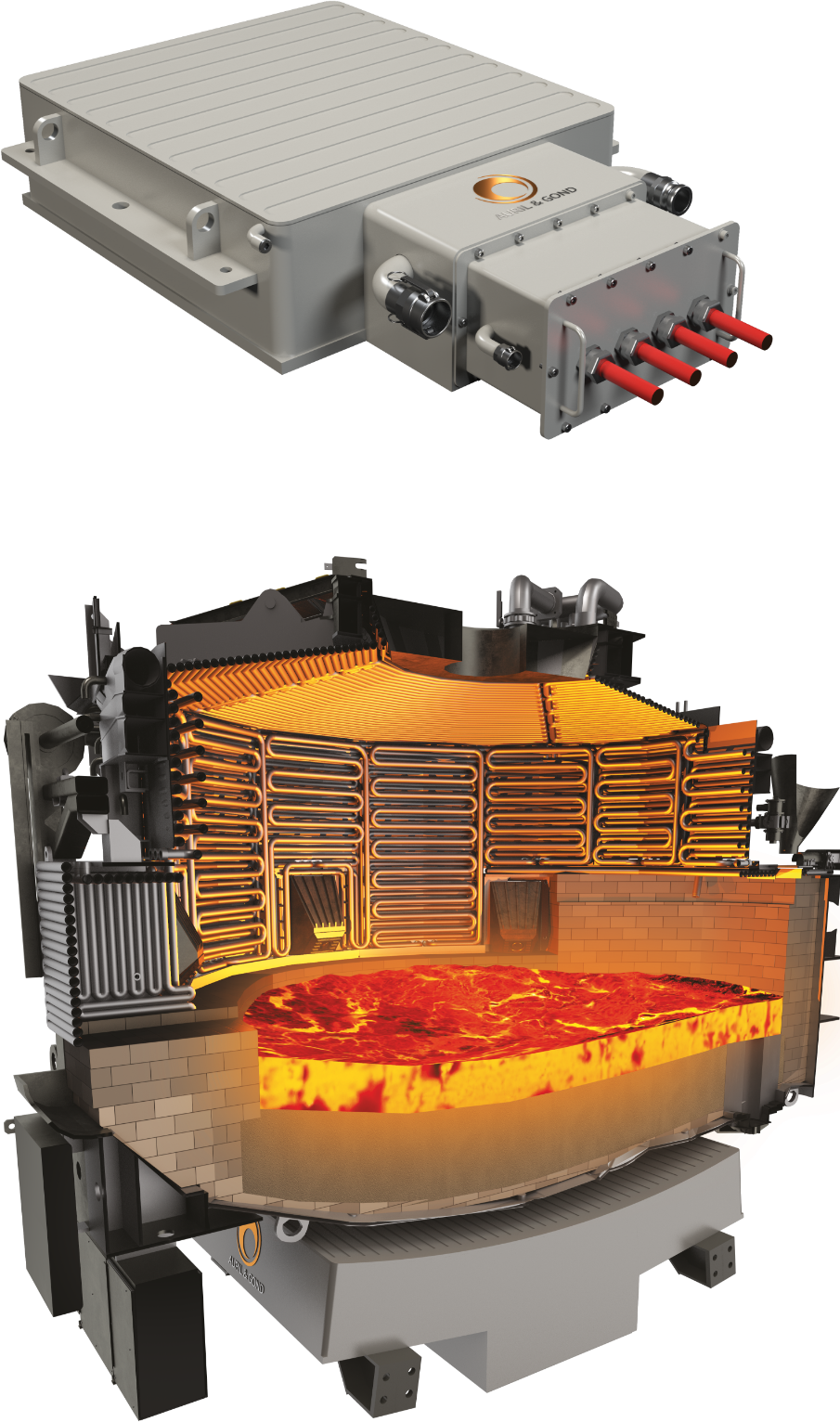

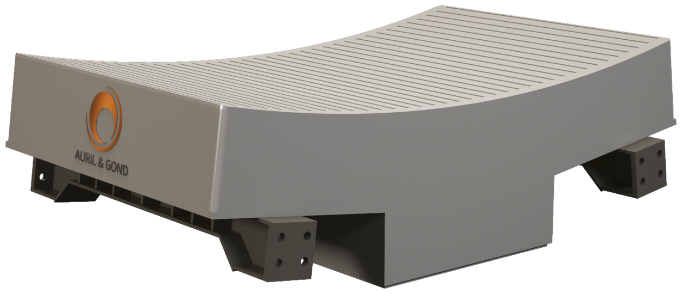

The life of the furnace is increased. It is not necessary to use burners at high temperatures for long periods and tap to tap time is reduced, guaranteeing greater heat exchange and higher productivity.

REDUCTION OF CONSUMPTION

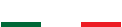

The AURIL&GOND stirrer reduces gas consumption by about 15% thanks to mixing with consequent homogenization of the temperature.

TEMPERATURE AND CHEMICAL HOMOGENIZATION OF THE ALLOYS

With the use of the electromagnetic stirrer we have a drastic reduction of the temperature difference between the upper and lower part of the molten bath which stands at less than 5°C a few minutes after switching on the stirrer. This difference without the use of the stirrer is normally between 50 and 80°C. This therefore also guarantees an increase in the speed of dissolution of the alloys in terms of time.

SLAG FORMATION REDUCTION UP TO 25%

The mixing effect produced by the AURIL&GOND stirrer allows lower temperature gradient in the liquid bath with a consequent lowering of the surface temperature. Using the stirrer makes less necessary argon gas mixing, as a result, slag formation is substantially reduced.

Watch the gallery

Do you have questions or need further information? We're here to help! Use our information request form to get in touch with us. We'll be happy to answer all your questions and provide the information you need.

Fields marked with (*) are mandatory.

We use cookies to personalize content, to get statistics and to improve your experience on our website.

We use cookies to personalize content, to get statistics and to improve your experience on our website.

For more information please read our Cookie Policy.

These cookies are necessary for the website to function and cannot be switched off in our systems.

You can set your browser to block or alert you about these cookies, but some parts of the site will not then work. These cookies do not store any personally identifiable information.

| Name | Provider | Domain | Duration | Description |

|---|---|---|---|---|

| XSRF-TOKEN | <span>W3</span>CMS | www.ems-ag.com | 120 minutes | This cookie was written to help with site security and prevent Cross-Site Request Forgery attacks. |

| laravel_session | <span>W3</span>CMS | www.ems-ag.com | 120 minutes | Internally laravel uses laravel_session to identify a session instance for a user. |

| laravel_cookie_consent | <span>W3</span>CMS | www.ems-ag.com | 180 days | The confirmation of a user's consent preference is stored internally. |

| laravel_cookie_consent_statistics | <span>W3</span>CMS | www.ems-ag.com | 180 days | This cookie is created to save the user's consent to use statistical cookies. |

| laravel_cookie_consent_marketing | <span>W3</span>CMS | www.ems-ag.com | 180 days | This cookie is created to save the user's consent to use marketing and targeting cookies. |

| laravel_cookie_consent_functions | <span>W3</span>CMS | www.ems-ag.com | 180 days | This cookie is created to save the user's consent to use functional and third-party cookies. |

| _GRECAPTCHA | Google reCAPTCHA | www.google.com | 6 months | Google reCAPTCHA sets this necessary cookie when it is run for the purpose of providing its risk analysis. |

These cookies allow us to count visits and traffic sources so we can measure and improve the performance of our site. They help us to know which pages are the most and least popular and see how visitors move around the site.

All information these cookies collect is aggregated and therefore anonymous. If you do not allow these cookies we will not know when you have visited our site, and will not be able to monitor its performance.

| Name | Provider | Domain | Duration | Description |

|---|---|---|---|---|

| _ga | Google Analytics | .ems-ag.com | 2 years | This cookie is used to distinguish unique users by assigning a randomly generated number as a customer identifier. It is included in every page request on a site and used to calculate visitor, session and campaign data for site analytics reports. |

| _gid | Google Analytics | .ems-ag.com | 1 day | This cookie is set by Google Analytics. Stores and updates a unique value for each page visited and is used to count and track page views. |

| _ga_* | Google Analytics | .ems-ag.com | 2 years | |

| _gat_* | Google Analytics | .ems-ag.com | 1 minute | It is a pattern type cookie set by Google Analytics, in which the pattern element on the name contains the unique identification number of the account or website to which it refers. It is a variation of the _gat cookie which is used to limit the amount of data recorded by Google on high-traffic websites. |

These cookies may be set through our site by our advertising partners. They may be used by those companies to build a profile of your interests and show you relevant adverts on other sites.

They do not store directly personal information, but are based on uniquely identifying your browser and internet device. If you do not allow these cookies, you will experience less targeted advertising.

No cookies used for this type

These cookies enable the website to provide enhanced functionality and personalisation. They may be set by us or by third party providers whose services we have added to our pages.

If you do not allow these cookies then some or all of these services may not function properly.

No cookies used for this type