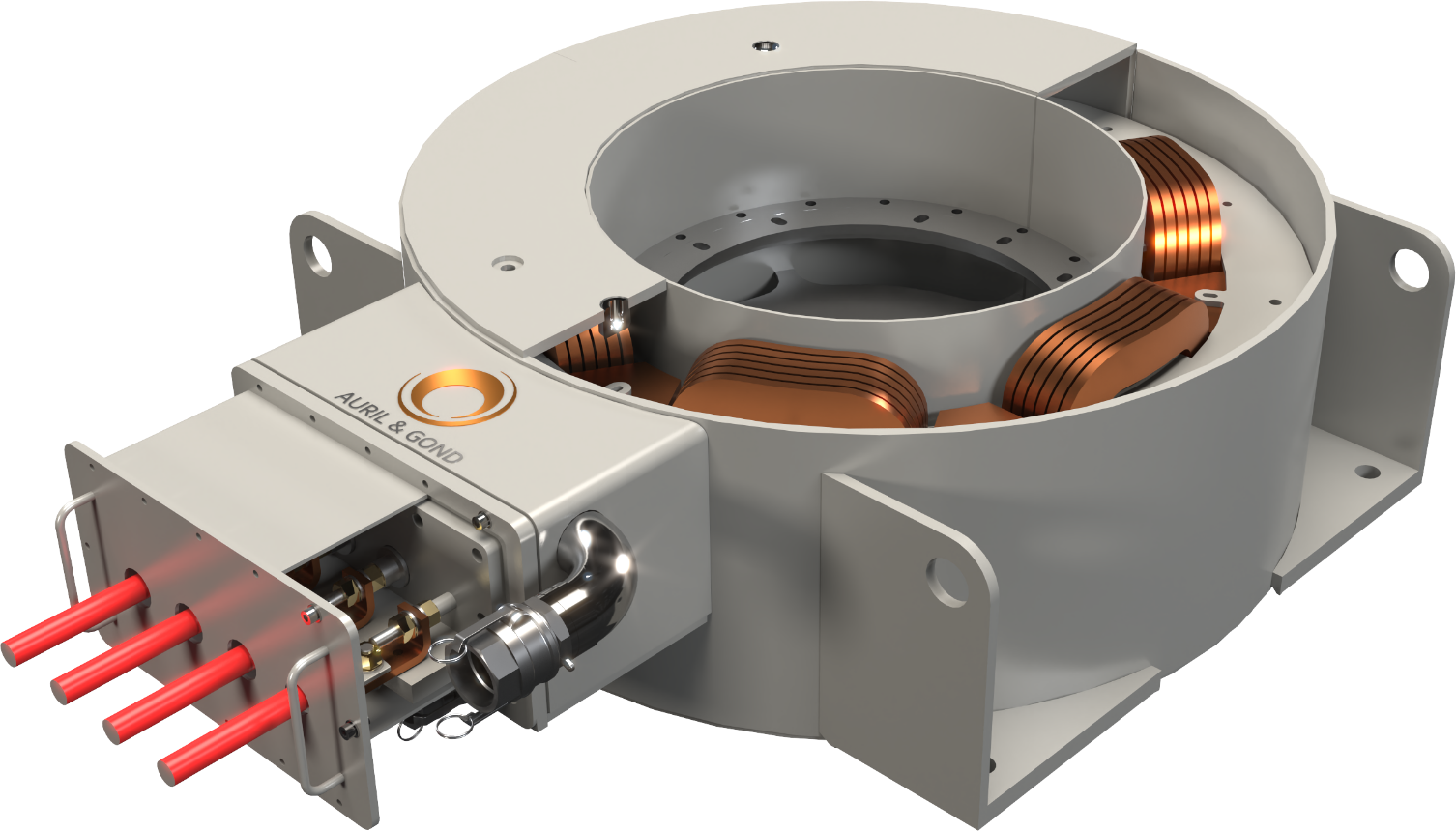

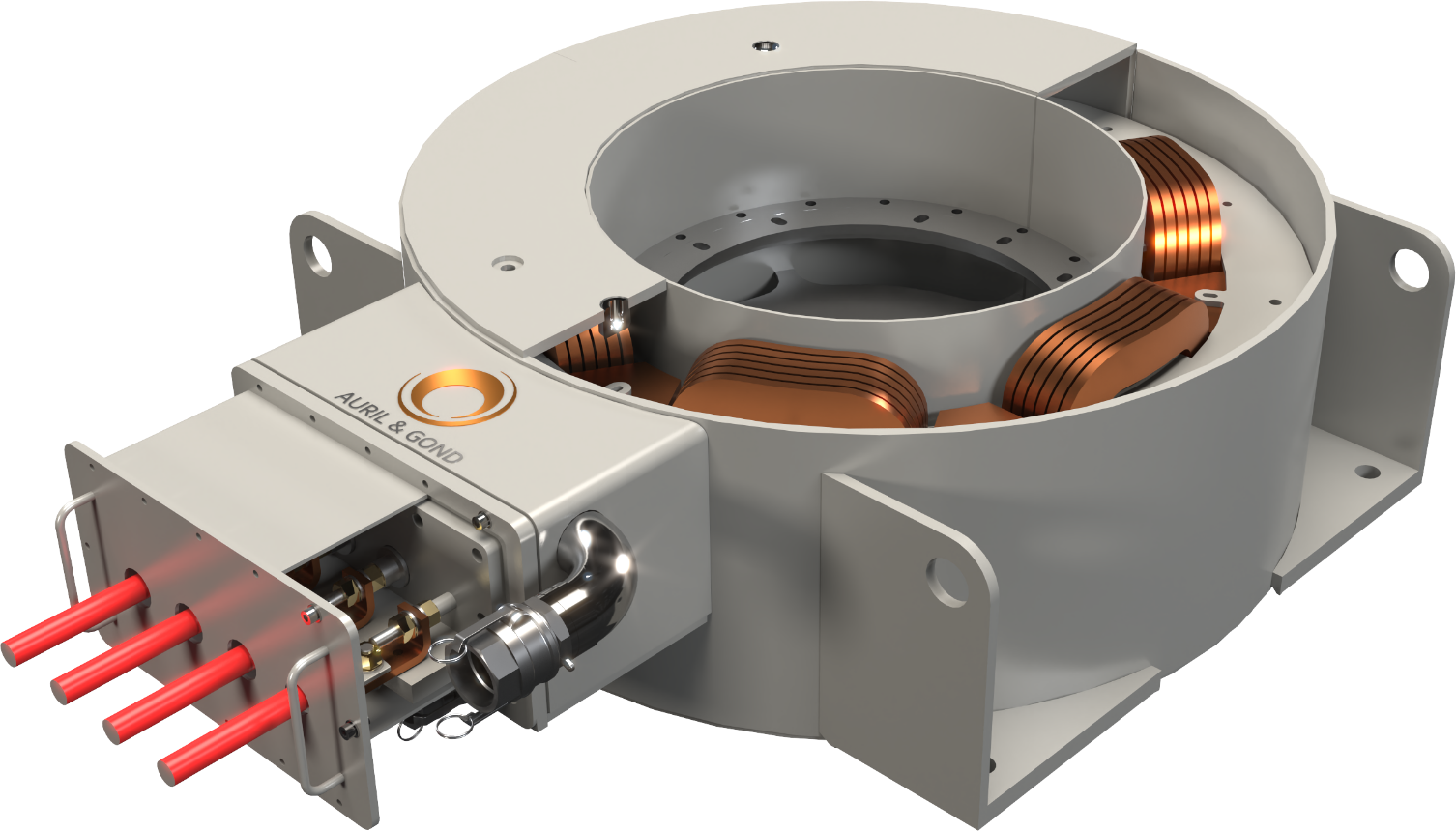

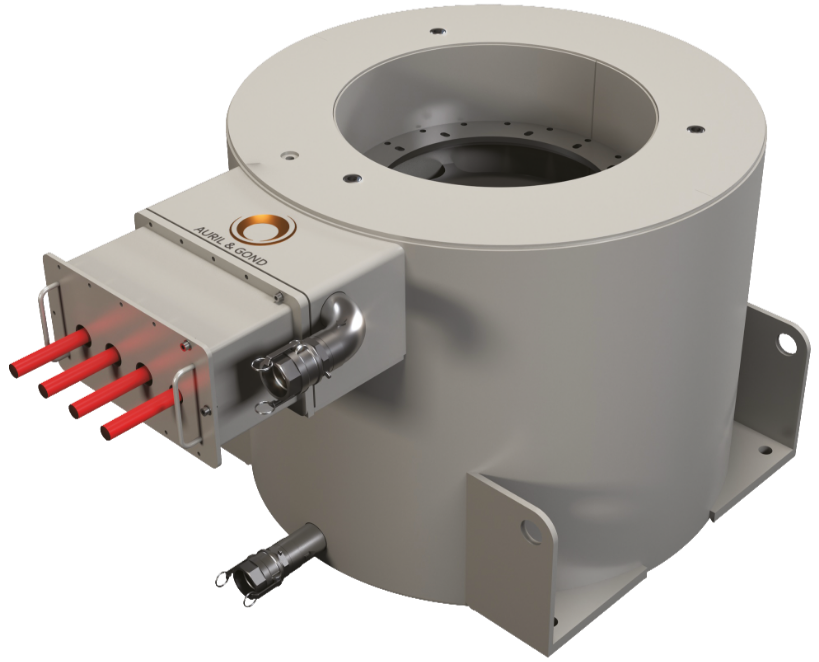

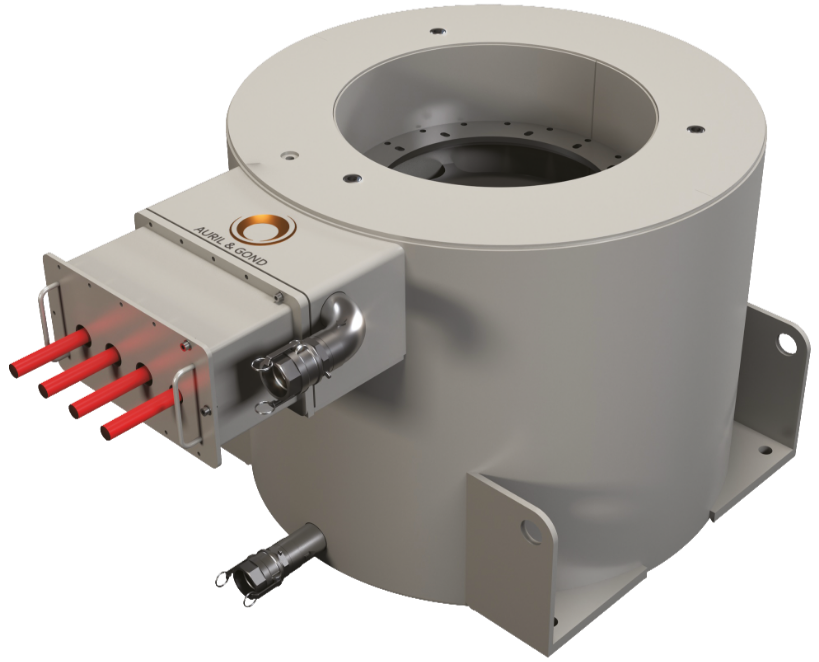

The electromagnetic stirrer (EMS) are widely used in the iron and steel industry both in the continuous casting phases and in the steel refining process in the ladle.

The use of the stirrers allows to increase the quality and the production of steel and, due to the high metallurgical flexibility they will fit perfectly to the production of steels with different carbon content.

The quality of the surface layer and the internal crystalline structure of the steel depend on the chemical composition, the sildification process and the flow of the liquid steel inside the casting line. In the presence of a variable magnetic field inside the liquid steel, volume forces are induced which impress a main rotation motion and secondary motions along the casting line. The mixing induced with the electromagnetic stirrers makes the heat exchange along the casting line more effective, consequently the solidification process is more homogeneous and promotes the formation of equiaxed zones.

Electromagnetic stirrer are user in continuous casting processes, mainly to increase the quality and the production of steel.

A&G stirring plants fit perfectly with existing equipment into the melt shop, as well as new designs.

Here the main technologies and operational precedures:

After many years of technical and operational experience and the highly specialized know-how, we are able to design and realize stirring systems based on the specific needs of the customer.

For the design phase of new stirring systems we use advanced fluid-dynamic computation software which is able to calculate and display the motions induced in the liquid steel by the variable magnetic field generated by the electric winding of the stirrer.

The multiphysic analysis software allows to solve the complex problems related to conductive fluids immersed in variable magnetic fields in a quick and precise way, thus succeeding in optimizing the design phase of the stirrer. The calculation of the electrical parameters of the stirrer, such as winding resistance and phase inductance, and the thermal behavior of the windings are also analyzed with the finite element simulation software. Computer-aided design is therefore a fundamental tool for developing and testing stirrers using mathematical models before they are put into production.

Watch the gallery

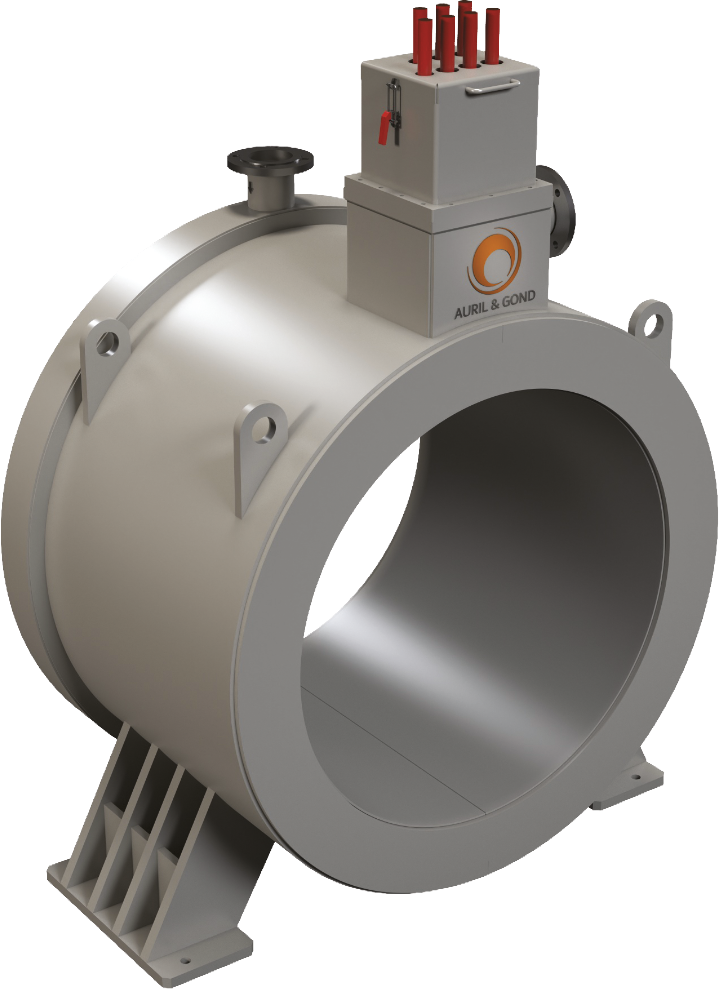

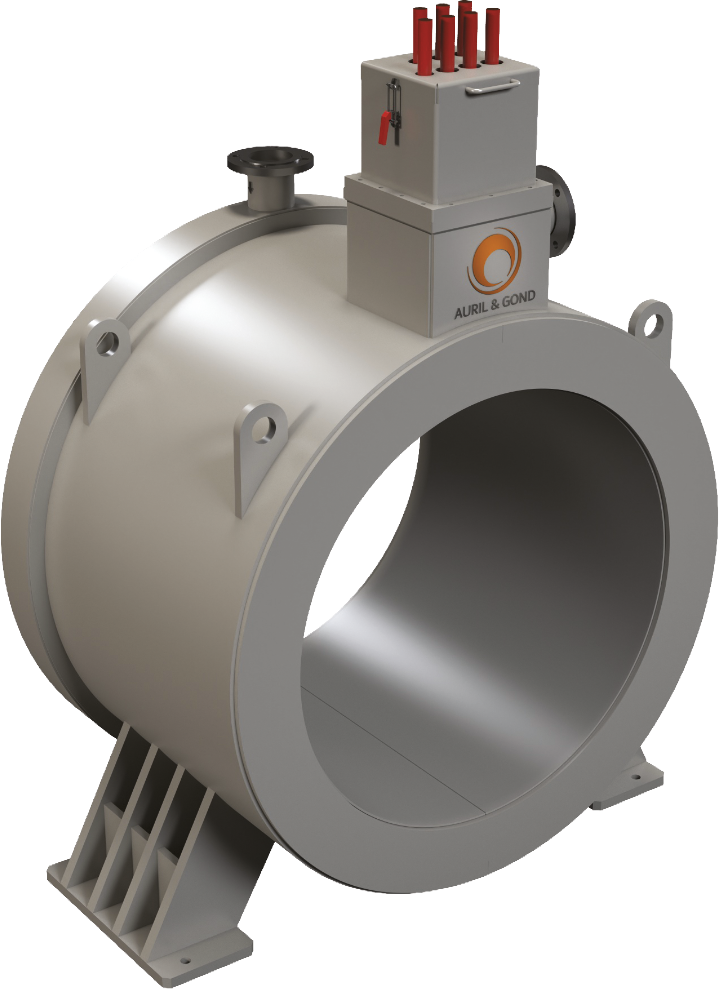

M-EMS, as the name indicate, is positioned in the initial part of the casting line where the primary cooling extract the heat from the mould to form a solidified shell of the as-cast semi product, billet, blooms and slabs.

M-EMS improves surface, sub-surface and inner strand quality, in terms of reduction of pinholes, center porosity and segregation in the cast product. It also helps to break down the columnar dendrites that are growing in solidification front to form fine equiaxed grain structure.

M-EMS increase the heat transfer between the liquid steel inside the mould and copper tube that permits to reduce the surface roughness of the cast product and improve the uniformity of the solidification shell thickness.

M-EMS is used to improve the quality for steel grades as low alloy steel, spring steel, cold rolling steel, medium and high carbon steel and all sections.

S-EMS is located below the mould in the secondary cooling zone where the liquid percentage of steel remains dominant.

Strand stirrer is used to increase the equiaxed zone and enhance the metallurgical benefits achieved with mould stirrer.

In fact extend the stirring effect along the casting line avoid dendrites to form again, which are the cause of centerline and segregation formation. S-EMS is normally used for all grades and typically for bloom sections.

F-EMS is located in the final solidification zone where solid and liquid phases coexist together (mushy zone). Final stirrer is used normally in combination with mould

and/or strand stirrer to further reduce the internal segregation and center porosity on high carbon and high alloy steels.

Compared to the other type of stirrer, the nominal power of the F-EMS is larger because they need more electromagnetic torque to stir the steel in the mushy zone, being characterized by smaller pool diameter and higher viscosity.

F-EMS also have different rotary stirring mode compared to M-EMS, in fact intermittent reversing stirring motion in the liquid steel is often used to limit the growth of columnar dendrites and break them into smaller fragments which improve the size of the equiaxed zone and thus also the internal soundness of the as-cast product.

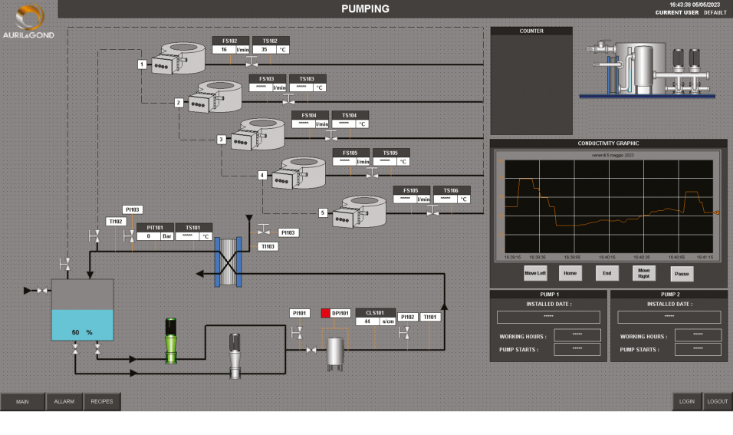

Our inverter switchboards are equipped with a sliding system that allows easy installation / maintenance of the main IGBT module. They are composed of static converters at impressed voltage with IGBT modules, digital regulation with vector control, capacitor bank, microprocessor control unit and auxiliary circuits (power supplies and transducers). The inverter is specifically designed for critical applications and is designed with the latest and proven technologies, in a modular design for easy installation and maintenance. All Power components are sized to ensure operation of the converter even in the most severe service and load conditions. The power components (diodes and IGBTs) are cooled by forced ventilation. The static converter is available in different sizes up to a maximum power of 4 MW in the case of 8 modules in parallel.

The cooling system with demineralized water it is used to remove the heat produced in the coils by Joule effect and to maintain the winding temperature below the limit value related to the thermal insulation class. The circuilation pumps can be supplied by variable frequency drive which allow to adjust the flow rate and the pressure of the cooling water. In case of steel grades casting, that doesn’t require the usage of the stirrer, its not necessary to remove them from the casting machine but you can simply decrease the water cooling flow to ensure a longer life of the electrical insulation of the stirrer. During the continous casting of special steel with reduced number of strands, its possible to reduce the flow rate of the pump in order to reduce the energy consumption.

Junction box allow connection between electrical supply cables coming from the inverter power output and the electrical cables that are going to supply terminals of the stirrer. Junction box is made of stainlesssteel AISI 304 and can be equipped with special locks on the basis of the Safety degree required by the application.

According to the installation requirements, junction box can be equipped with copper bars, non-fusible disconnect switches or fuses for overload protection.

Our transformers are manufactured using carefully selected materials that enable us to provide a high quality product by offering tailor-made solutions that meet every customer’s needs. The transformers are used to obtain the IT earthing system which allows to reduce the supply harmonic current content that can effect the electrical power quality, improving the continuity of service by reducing the fault current and increase the power factor.