The production of aluminum consists in a production process that is divided into several very complex stages and the electromagnetic stirrer has become a fundamental element to accelerate the reactions during the melting phases. Auril & Gond supplies a complete system that can be mounted either below or to the side of the furnace. The movement of the metal is created by the interconnection between the magnetic field generated by applying electrical energy to the coils, and the molten bath. A movement on the molten aluminum by using an electromagnetic stirring (EMS) is a solution that brings significant advantages including, the elimination of mechanical contact with the molten liquid while improving key parameters such as melting speed and energy efficiency.

Thanks to fluid dynamics computation software, we carry out an analysis of the motions generated by the stirrer on the molten bath, which allow us to provide the customer with a system suitable for his needs.

Among the strengths of our system we find a very low maintenance, almost negligible, and the possibility of use on all conductive liquids

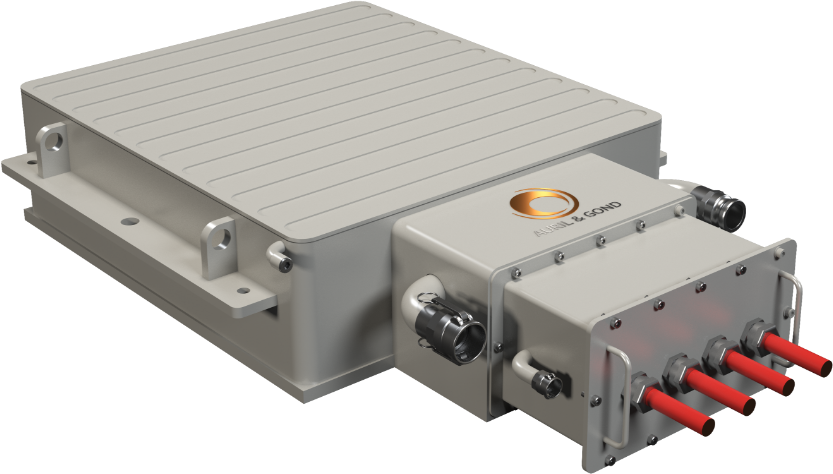

Auril&Gond stirrer can be mounted on different types of furnaces including melting furnaces, holding furnaces or chamber furnaces and can be supplied with both air or water cooling solutions according to the needs of the customer and the production plant.

In order to install the EMS it is necessary to have a non-magnetic steel "window" to ensure the mixing of the material and a space for the installation of the stirrer itself.

Auril & Gond stands out for the great reliability and quality of a made in Italy product and for a team able to follow the customer from the design phase to the final commissioning phase.

Thanks to the reduction of heat losses and the improvement of heat transfer in the bath, energy savings are obtained and can reach 15% less.

Our inverter switchboards are equipped with a sliding system that allows easy installation / maintenance of the main IGBT module. They are composed of static converters at impressed voltage with IGBT modules, digital regulation with vector control, capacitor bank, microprocessor control unit and auxiliary circuits (power supplies and transducers). The inverter is specifically designed for critical applications and is designed with the latest and proven technologies, in a modular design for easy installation and maintenance. All Power components are sized to ensure operation of the converter even in the most severe service and load conditions. The power components (diodes and IGBTs) are cooled by forced ventilation. The static converter is available in different sizes up to a maximum power of 4 MW in the case of 8 modules in parallel.

Our transformers are manufactured using carefully selected materials that enable us to provide a high quality product by offering tailor-made solutions that meet every customer’s needs. The transformers are used to obtain the IT earthing system which allows to reduce the supply harmonic current content that can effect the electrical power quality, improving the continuity of service by reducing the fault current and increase the power factor.